When we talk about diaphragm pumps, there are generally three types that are most commonly used in industries. Each has its own set of applications, advantages, and limitations. Let’s break them down one by one.

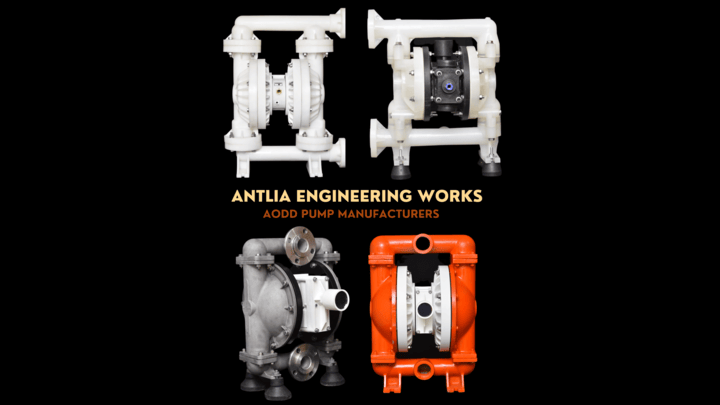

This is the most commonly used type of diaphragm pump. Even within AODD pump, there are two variations.

As the name suggests, this pump is designed for transferring dry powders. While it serves a niche purpose, there are quite a few limitations—especially with the kind of powders it can handle and the distance it can transfer them. So it’s not as versatile as the liquid-handling types, but where powder transfer is needed, it gets the job done.

This is the latest addition to the diaphragm pump family. The biggest advantage of an EODD pump is the running cost, which is almost one-third compared to an AODD pump since it uses an electric motor instead of compressed air.

But, there are a couple of drawbacks:

Because of these reasons, EODD pumps are currently only feasible in setups where pumps are required to run for more than 16 hours a day—making the savings on running costs justify the investment.