Air Operated Double Diaphragm (AODD) pumps are essential for handling corrosive, abrasive, and shear-sensitive fluids. Correct installation is the cornerstone of a long service life and consistent performance.

This guide walks through the basic installation steps, air supply setup, and initial operation checks for an AODD pump, based on standard site practices.

.jpg)

An AODD pump operates using compressed air, which alternately moves two diaphragms to create suction and discharge. This design allows the pump to handle corrosive, abrasive, viscous, and shear-sensitive fluids without the use of electricity.

Because air is the driving force, air quality, pressure regulation, and proper connections directly affect pump performance.

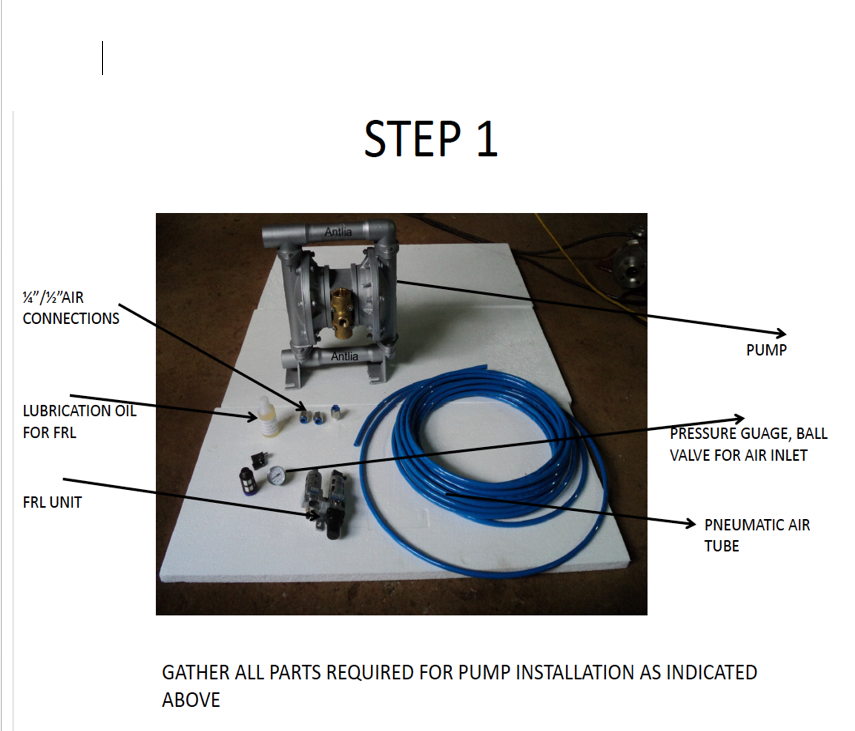

Before installing the pump, ensure the following:

Preparing these basics reduces installation errors and avoids early operational issues.

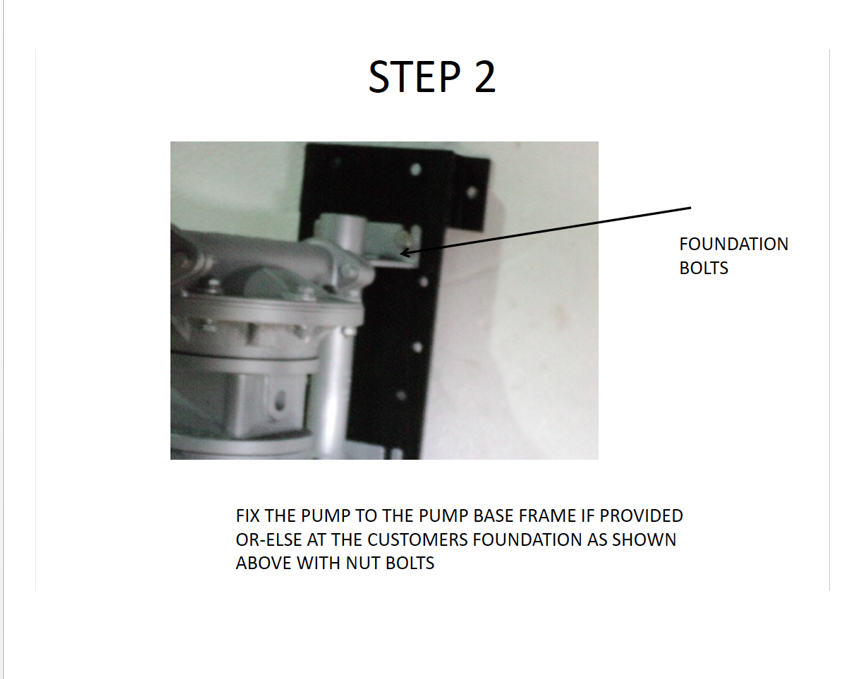

The pump should be securely mounted on a stable foundation or base frame using appropriate bolts. Proper mounting helps minimize vibration and ensures safe operation during continuous duty .

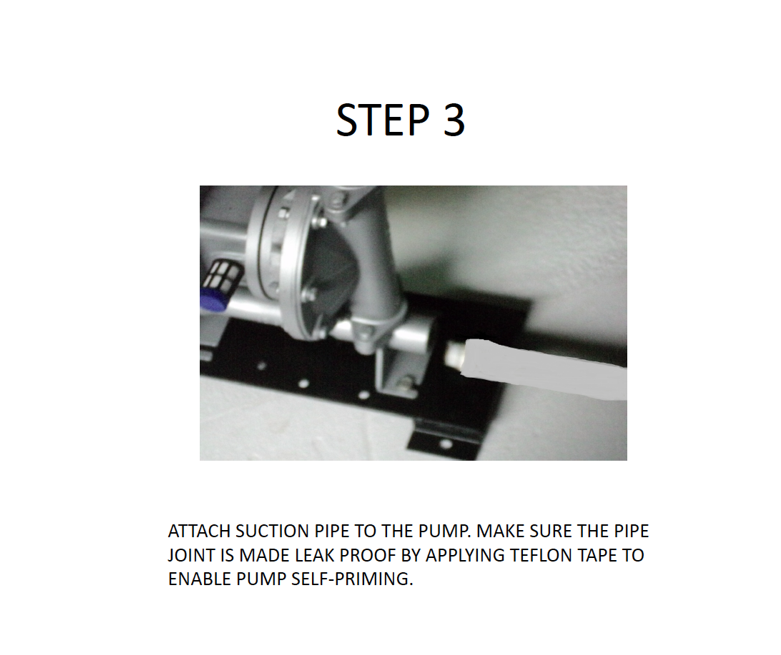

Attach the suction pipe to the pump inlet using leak-proof joints. Applying Teflon tape on threaded connections helps prevent air ingress, which is essential for proper self-priming.

A poorly sealed suction line is one of the most common reasons for reduced flow or inconsistent pumping.

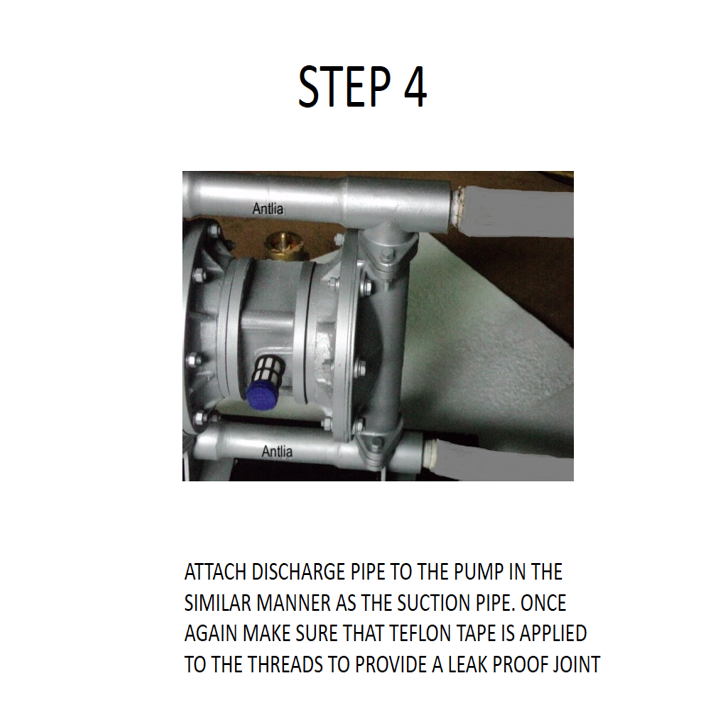

Connect the discharge pipe in the same manner as the suction line. Ensure all joints are properly sealed and aligned to avoid unnecessary stress on the pump casing .

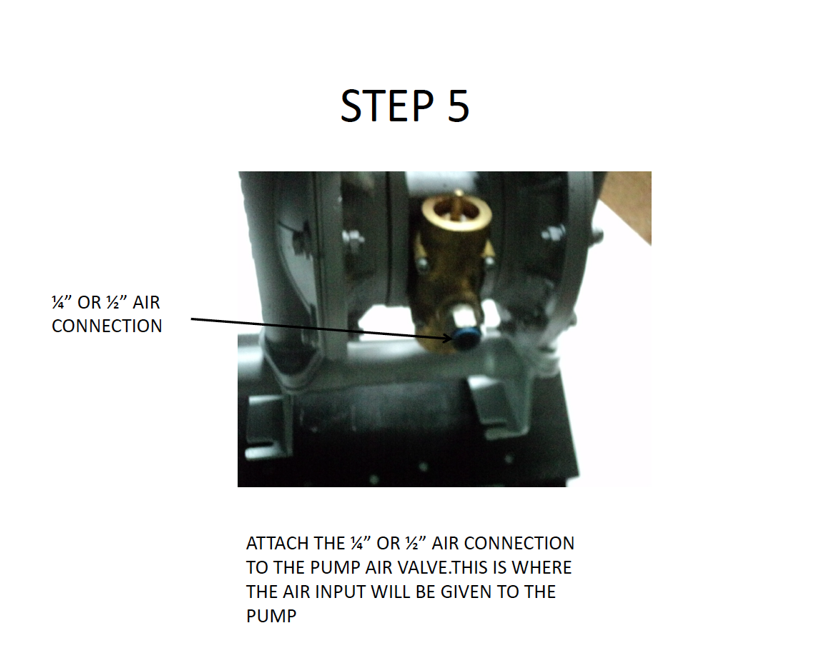

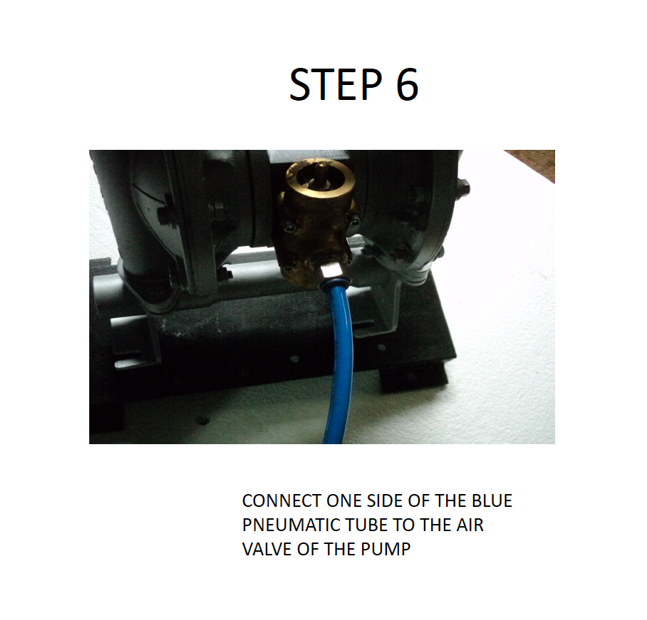

Connect the compressed air line (typically ¼” or ½”) to the pump’s air inlet valve. This is where regulated air enters the pump to drive diaphragm movement.

An FRL (Filter, Regulator, Lubricator) unit is critical for AODD pump operation. It:

The FRL unit should be connected between the air compressor and the pump using pneumatic tubing.

Set the air pressure gradually using the regulator and monitor it through the pressure gauge. Lubrication oil (typically SAE 40 grade) is added to the lubricator to ensure smooth internal valve operation.

Once all connections are complete:

If the pump does not start immediately, the air valve release pin can be pressed to free any jammed internal components.

Some issues encountered during operation include:

Regular inspection of air lines, diaphragms, and valves helps prevent unexpected downtime.

AODD pumps are robust and forgiving, but proper installation and air system setup are essential for reliable performance. Paying attention to mounting, piping, air regulation, and lubrication significantly improves efficiency and extends pump life.

Understanding these basics allows operators and maintenance teams to get the best out of an AODD pump in real plant conditions.