Air-operated double-diaphragm pumps (AODD) are preferred in wide applications because of their simple design which makes them easy to operate and maintain. To achieve peak performance, end users must install and operate these pumps precisely. Within a matter of minutes, the common issues can be corrected with the right information. Here are six quick steps that will help you fix common problems occurring during installation and operation.

1. Check the inlet air line size and pressure.

2. Inspect for muffler icing and restrictions.

Diaphragm pumps can generate high decibels at high speed, this is one of the main reason mufflers are recommended during installation. AODD pump requires compressed air to operate. As the compressed air enters the air valve and channels through the pump center section to exhaust through the muffler, a rapid temperature change occurs. At the muffler exhaust, air temperature is below freezing and can cause icing-related issues that are common in humid environments.

Inconsistent pump operation, supplied air with high levels of moisture or visible frost on the outside of the muffler are indications of an icing-related issue resulting in low pump efficiency. Here are few suggestions to eliminate these issues:

Solutions to icing can range depending on the application and environmental conditions, but reducing the air pressure to the pump is one of the quickest and most effective way to reduce icing.

3. Inspect sealing surfaces for leakage.

A wise technician once said, “There are two types of pumps those that leak and those that are about to leak.”

Leakage is a common problem in all pump types. A few simple fixes can ensure the liquid stays in an AODD pump. Materials relax over time which are often referred to as deformation which can cause sealing surfaces to loosen and create leak paths. Follow the bolting patterns to reduce the threat of leakage.

Reuse of polytetrafluoroethylene (PTFE) O-rings or Gaskets is another cause of leakage at sealing surfaces. The elasticity of PTFE is low. Once a PTFE O-ring or Diaphragms has been compressed, they not capable to spring back to its original shape. Replace all pump PTFE products when servicing an air operated double diaphragm pump.

4. Ensure proper tubing and piping size.

Diaphragm Pump suction and discharge port diameters may vary based on the application. Inlet and outlet hose sizes must match the pump’s size. The major concern is the risk of cavitation, which leads to frequent repair and maintenance needs. Replacing tubing and piping size after installation is relatively quick. Knowing the accurate size at time of installation eliminates the effort required to make an alteration later.

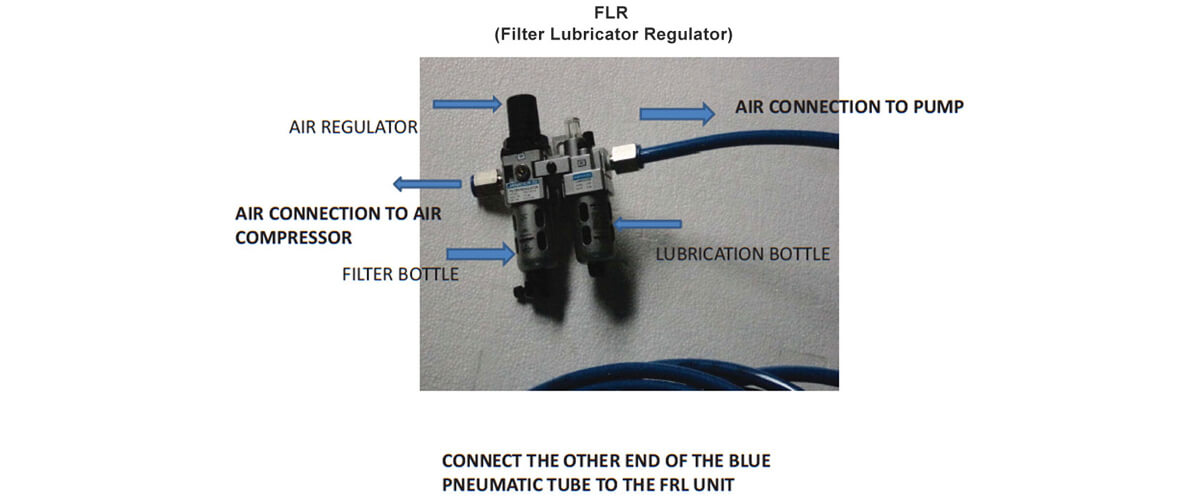

5. Slow the pump down to prime - Using FLR Unit

Double Diaphragm pumps are well known for its characteristic of self-priming. Creating a low-pressure zone i.e. less than atmospheric pressure inside the liquid chambers is how the pump draws fluid. If supplied air pressure is too high, there will be a quick transition in the pump and there won’t be enough time for the fluid to be drawn into the pump.

To solve this priming issue in a matter of seconds, slow down the diaphragm pump by using the air regulator to decrease the inlet air pressure. Once the pump speed has been reduced and made sure the liquid has enough time to enter the pump, increase the air pressure and operate the pump at high speed.

6. Clear any fluid line restrictions.

Certain limitations create backpressure that may negatively affect the pump and likely to create cavitation that will increase repair and maintenance needs. Inspect the pump and piping connections to ensure there are no visible restrictions. Look for the following at both the pump’s suction and discharge: